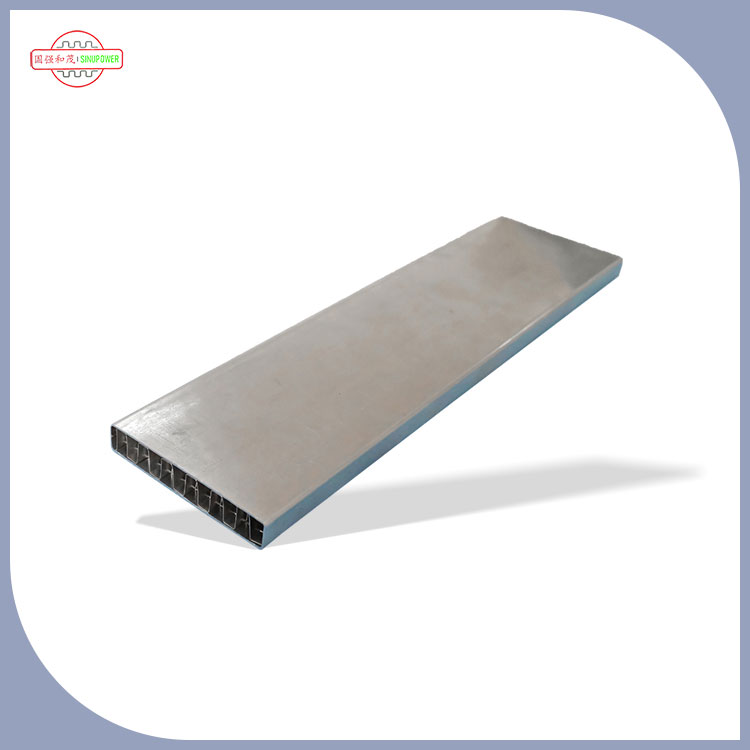

Liquid Cooling Plate Cold Plate Tube are mainly used in the field of new energy vehicles for battery thermal management systems and heat dissipation of motors and electronic control systems, as follows:

1.Battery thermal management system

Cooling battery: The battery pack of new energy vehicles generates a large amount of heat during operation. The Liquid Cooling Plate Cold Plate Tube through the internal cooling liquid, quickly absorbing the battery heat and transferring it to the external heat dissipation device, ensuring that the battery operating temperature is stable within the optimal range of 15-35 ℃. The Tesla Model 3/Y uses die cast aluminum alloy liquid cooling plates, which integrate cooling channels directly inside the plate. Through fine channel design, the coolant is evenly distributed, significantly improving cooling efficiency and reducing the risk of local temperature rise.

Preventing thermal runaway: CATL's Kirin Battery places a water-cooled plate in the middle of the battery pack, which not only increases the cooling area but also reduces the heat conduction between adjacent cells, preventing chain reactions caused by thermal runaway of a single cell and improving the safety of the battery.

2.Heat dissipation of motor and electronic control system

Motor shell heat dissipation: The motor generates a large amount of heat during high-power operation. The aluminum motor shell quickly transfers heat to the external heat dissipation device through internal designed heat dissipation channels, such as spiral shaped cold plate tubes, combined with natural convection and liquid cooling assistance. For example, a certain electric vehicle model uses a die cast aluminum alloy motor housing, which reduces the operating temperature of the motor by 15% -20% compared to traditional solutions, improving overall efficiency and lifespan.

Heat dissipation of electronic control system: The electronic control system is sensitive to temperature fluctuations. By optimizing the cross-sectional shape and arrangement of the internal cooling channels of the Liquid Cooling Plate Cold Plate Tube, the heat dissipation area is increased and the wind resistance coefficient is reduced. For example, a certain electronic control unit radiator is manufactured using die-casting technology to effectively control temperature fluctuations under high load conditions, ensuring stable system operation.

Power module heat dissipation: For IGBT, GTO and other power modules in new energy vehicles, liquid cooled plate tubes can control their temperature so that they do not exceed the specified maximum temperature under working conditions, achieving safe, stable and reliable operation of the power module and extending the service life of the equipment.