The main pipe (also commonly referred to as the "manifold" or "main pipe") of a a head pipe for parallel flow condenser is one of its core structural components, which directly determines the heat transfer efficiency, system stability, and operational reliability of the condenser. Its role can be expanded from four core dimensions: medium distribution/collection, structural support, pressure balance, and heat exchange assistance, as follows:

1、 Core function: Accurately allocate and collect refrigerants to ensure heat exchange efficiency

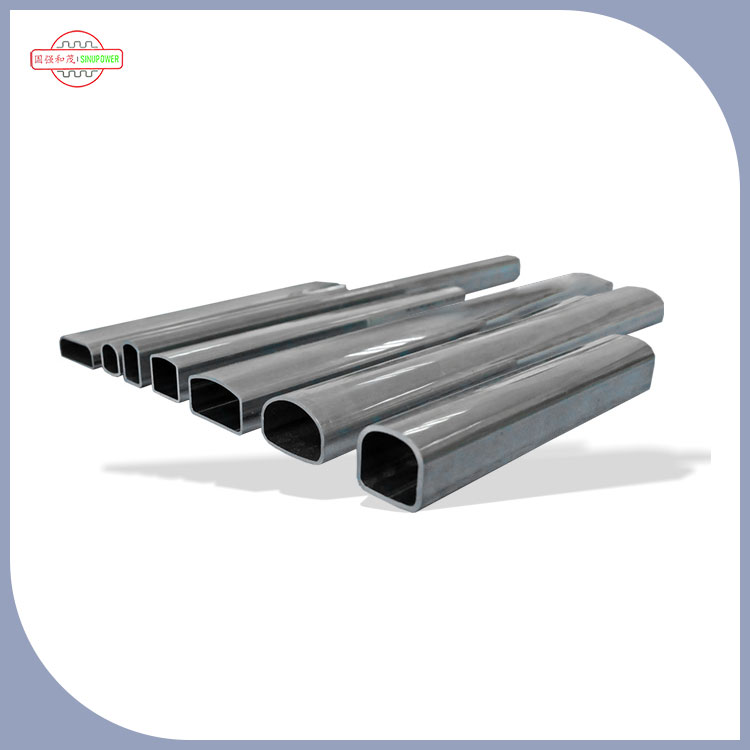

This is the most crucial role of a supervisor. The core heat exchange unit of a parallel flow condenser is "main pipe+flat tube+fins", where the main pipe is divided into an inlet main pipe and an outlet main pipe, which work together to achieve efficient refrigerant flow:

Entrance supervisor: evenly distribute refrigerant

The high-temperature and high-pressure gaseous refrigerant discharged from the compressor first enters the inlet main pipe. The supervisor will distribute the refrigerant evenly into dozens of parallel flat tubes through "diversion holes" or "diversion structures" internally (flat tubes are the main channels for refrigerant to exchange heat with air).

If the distribution is uneven, some flat tubes may become "heat saturated" due to excessive refrigerant, while others may become "empty tubes" due to insufficient refrigerant, directly reducing the overall heat transfer efficiency of the condenser and even causing a high pressure alarm in the system.

Export supervisor: Collect and guide refrigerant

After completing heat exchange with external cold air in the flat tube, the refrigerant condenses from a "gaseous" state to a "gas-liquid mixture" or "liquid" state, and then flows into the main outlet pipe. The supervisor collects all the refrigerant in the flat tubes and sends it to the throttling device (such as an expansion valve) through the outlet pipeline to complete the next stage of the refrigeration cycle.

The export supervisor will also use a "liquid accumulation structure" (such as a bottom groove) to ensure that liquid refrigerant flows out first and reduce the entry of gaseous refrigerant into the throttling device (to avoid a decrease in throttling efficiency).

2、 Structural support: Fixed heat exchange unit to ensure overall stability

The flat tubes and fins of the parallel flow condenser need to be fixed by the main pipe to form a rigid whole:

Supervisors usually use high-strength aluminum alloy material (lightweight, good thermal conductivity), which is tightly connected to flat pipes through "mechanical expansion" or "brazing" processes. It can not only withstand the high pressure of refrigerant (usually 1.5-3.0 MPa), but also resist external impacts such as vehicle driving and equipment vibration.

If there is no fixed supervisor, dozens of thin flat tubes will break due to uneven stress, causing refrigerant leakage and directly damaging the condenser.

3、 Pressure balance: Buffer refrigerant fluctuations to protect system safety

During the operation of the refrigeration system, the pressure of the refrigerant may fluctuate due to working conditions such as compressor start stop and changes in ambient temperature. The main pipe can buffer the pressure through the following methods:

Volume buffer: The main pipe has a certain volume inside, which can temporarily accommodate the "excess" refrigerant caused by sudden pressure rise, avoiding the system pressure from instantly exceeding the safety threshold (such as when the compressor discharge pressure is too high, the main pipe can alleviate the impact of high pressure on the flat pipe).

Gas liquid separation assistance: In the outlet main pipe, gaseous refrigerant will accumulate in the upper part of the main pipe due to low density, while liquid refrigerant will deposit in the lower part due to high density. The "upper and lower layered" structure of the main pipe can assist in separating gas and liquid, reducing the risk of "liquid hammer" (if liquid refrigerant directly enters the compressor, it will cause damage to the compressor).

4、 Heat exchange assistance: reduces local thermal resistance and improves overall heat transfer efficiency

Although the supervisor is not the main heat exchange component, they can assist in heat exchange through material and structural design:

Material thermal conductivity: The aluminum alloy used for the main pipe has a thermal conductivity of about 200W/(m · K), which is much higher than that of ordinary steel material. It can further diffuse the heat transferred by the flat pipe into the air, reducing local heat accumulation (such as when the temperature near the inlet main pipe is high, the main pipe can assist in heat dissipation to avoid cracking at the connection between the flat pipe and the main pipe due to excessive temperature difference).

Structural optimization: Some of the outer walls of the main pipes will be designed with "micro fins" or "grooves" to increase the contact area with the air, indirectly improving heat dissipation efficiency (especially in compact spaces such as vehicle air conditioning, this design can compensate for the problem of insufficient heat exchange area).