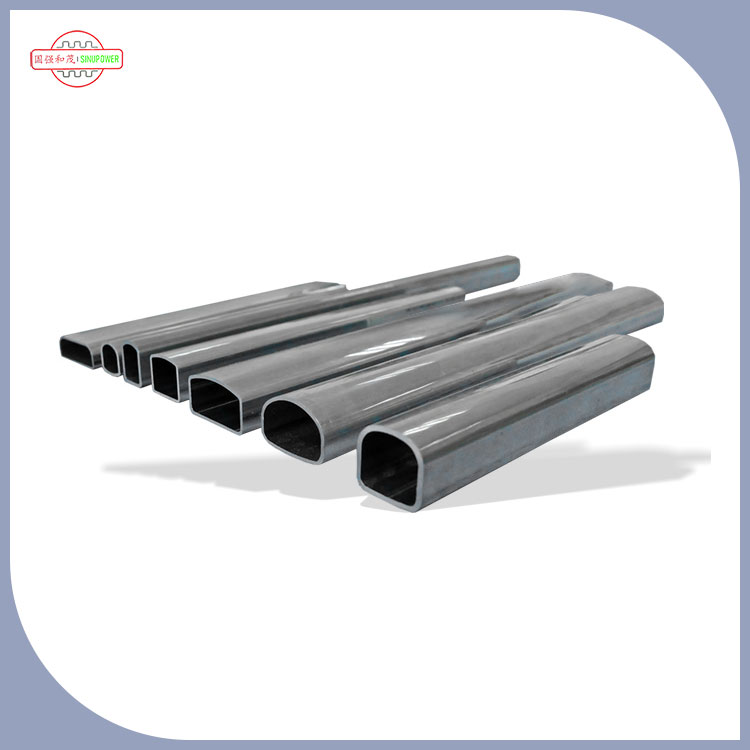

The factory chooses D-Type Condenser Header Aluminium Pipe based on their comprehensive advantages in heat transfer efficiency, cost control, structural adaptability, and other dimensions, which can accurately match the core requirements of industrial condensers (such as air conditioning refrigeration systems, chemical heat exchange equipment, refrigeration units, etc.). The following provides a detailed analysis of the reasons for its widespread adoption from three aspects: technical characteristics, adaptability to industrial scenarios, and cost-effectiveness

1、 Technical features: Adapt to the core requirements of efficient heat exchange and stable operation of condensers

The "D-type" (flat cross-section instead of traditional circular shape) of the aluminum tube for the D-type condenser header is the key design, which, combined with the material advantages of the aluminum tube itself, directly solves the core pain point of the condenser:

1. Significantly improve heat transfer efficiency (core advantage)

The core function of the condenser is "heat dissipation/exchange", and the D-type structure enhances this ability from two aspects:

Increasing the effective heat transfer area: When traditional circular aluminum tubes come into contact with fins (metal plates that assist in heat dissipation in condensers), it is only a "line contact" and the heat transfer area is limited; The flat cross-section of D-type aluminum tubes is in surface contact with the fins, and the contact area is increased by 30% -50% compared to circular tubes (depending on the flatness of the D-type), resulting in more direct and faster heat transfer.

Optimizing fluid flow state: The flat channels inside the D-tube can change the flow trajectory of fluids (such as refrigerants and cooling water), reduce the "flow dead zone" (fluid retention area, prone to fouling and inefficient heat transfer), and enhance the turbulence level of the fluid - the heat exchange efficiency between the fluid and the tube wall in turbulent state is 2-3 times higher than that in laminar state, further reducing the condensation temperature and improving the cooling/heat transfer efficiency of the system.

2. Enhance structural stability and reduce leakage risk

Industrial condensers often require long-term operation in environments with vibrations (such as mechanical vibrations during unit operation) and temperature fluctuations (alternating cold and hot). The structural design of D-Type Condenser Header Aluminium Pipe is more suitable for this scenario:

Stronger resistance to vibration and deformation: The "flat rigidity" of the D-section is superior to that of a circular pipe. Under the same wall thickness, the bending and torsional strength of the D-section pipe is higher, which can reduce pipeline deformation caused by unit vibration; Meanwhile, the surface contact fin connection method (usually fixed through tube expansion technology) is more secure than the wire contact of circular tubes, reducing the risk of fin detachment and pipe loosening after long-term operation.

The corrosion resistance and lightweight advantages of aluminum tube material: Aluminum itself has good corrosion resistance (easy to form oxide film on the surface, isolate air and moisture), and its density is only about one-third of that of steel tube - compared with traditional steel tube headers, D-type aluminum tubes can reduce the overall weight of condensers (reduce equipment installation and transportation costs), while avoiding the problems of steel tube rusting and regular maintenance, especially suitable for humid and dusty industrial workshop environments.

2、 Industrial scenario adaptability: meeting the actual needs of factories with high production capacity and low maintenance

The production scenario of the factory has rigid requirements for equipment such as "continuous operation, low failure, and easy maintenance", and the design of the D-Type Condenser Header Aluminium Pipe perfectly meets these requirements:

1. Adapt to large-scale production and reduce assembly costs

Standardization and ease of processing: The cross-sectional shape of D-type aluminum tubes can be mass-produced through extrusion technology, with high dimensional accuracy (such as flatness and wall thickness deviation controlled within ± 0.1mm), and can be quickly matched and assembled with standardized fins; Meanwhile, aluminum has good ductility, and D-shaped tubes can be flexibly processed according to the structural requirements of the condenser (such as bending and splicing), reducing customization costs.

Compatible with automated assembly lines: Factory condenser production often uses automated assembly lines. The flat structure of the D-shaped tube facilitates precise grasping and positioning by the robotic arm, and the surface contact fin connection can be completed in one go through an automated tube expansion machine. The assembly efficiency is increased by more than 20% compared to circular tubes, meeting the high production capacity needs of factories.

2. Reduce maintenance costs and extend equipment lifespan

Anti scaling and easy cleaning: The turbulent flow inside the D-shaped tube can reduce the deposition of scale and impurities on the tube wall (scaling can reduce heat transfer efficiency, traditional circular tubes require regular acid cleaning and descaling); Even if a small amount of scale is generated, the flat lumen is easier to clean by high-pressure water flushing, reducing downtime for maintenance (factory downtime of 1 hour may cause tens of thousands of yuan in losses, low maintenance means higher production continuity).

Compatible with multiple working fluids: Industrial condensers have a variety of heat exchange fluids (such as R32, R410A refrigerants, or cooling media in chemical production), and aluminum tubes have good chemical stability and do not react with most working fluids; The D-type structure has strong fluid adaptability, which can meet the flow requirements of high-pressure refrigerants and also adapt to low viscosity cooling water. Its application scenarios cover most types of factories such as home appliance manufacturing, chemical industry, food processing, and automotive parts.

3、 Economy: Balancing "performance" and "cost" to meet the factory's demand for cost reduction

When factories choose equipment, they will comprehensively consider the "initial procurement cost+long-term operating cost", and the D-Type Condenser Header Aluminium Pipe has advantages in both aspects:

Lower initial procurement costs: The raw material price of aluminum is lower than that of copper (commonly used copper tubes in traditional high-end condensers), and the production process of D-type tubes is mature (extrusion molding), with batch production costs 40% -60% lower than circular copper tubes; At the same time, lightweight design reduces the overall material usage of the condenser (such as brackets and shells that can be adapted to thinner and lighter materials), further reducing equipment procurement costs.

Long term operating costs are better: on the one hand, higher heat exchange efficiency can directly reduce the energy consumption of the condenser (for example, refrigeration units can reduce the operating power of compressors, and data shows that D-type aluminum tube condensers are 5% -10% more energy-efficient than circular copper tube condensers); On the other hand, the corrosion resistance and low maintenance characteristics of aluminum tubes reduce the cost of later maintenance and replacement (such as pipe replacement to avoid rusting of steel pipes or high maintenance costs of copper pipes), making long-term use cost-effective.