Abstract

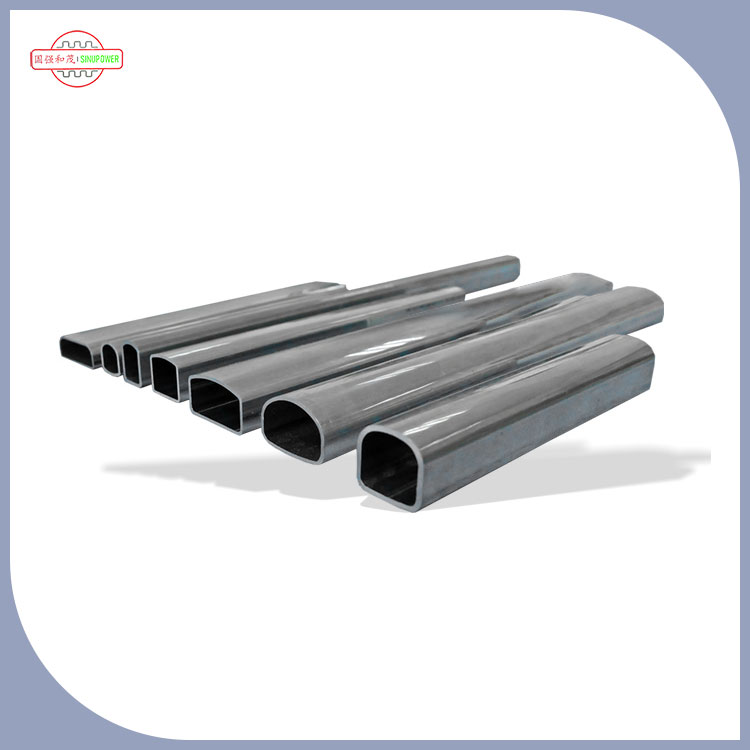

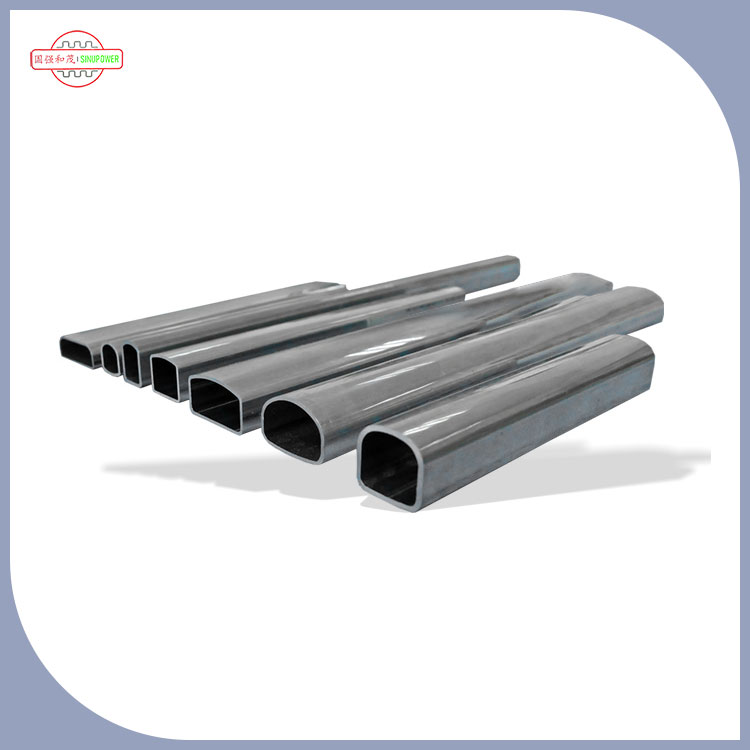

When a condenser underperforms, the symptoms look familiar: higher energy draw, unstable outlet temperatures, frequent cleaning, premature leaks, and the kind of vibration noise that keeps showing up at the worst possible time. A D-type Round Condenser Tube is often chosen in compact condenser builds because it helps balance three competing needs: heat-transfer surface utilization, flow stability, and mechanical robustness in a limited footprint. In this article, I break down what typically goes wrong in real-world condensers, what “D-type + round” design intent usually means, what to specify to avoid sourcing mistakes, and how to think about durability (corrosion, fouling, vibration) before the tube ever reaches your shop floor.

Table of Contents

- Outline at a glance

- What problems are buyers trying to solve?

- What is a D-type Round Condenser Tube in practice?

- Where does it fit best in condenser systems?

- What to specify so performance matches the drawing

- How to think about corrosion, fouling, and vibration

- Supplier questions that prevent expensive rework

- Selection & troubleshooting table

- FAQ

- Closing thoughts

Outline at a glance

- First: identify the pain point (space, pressure drop, vibration, corrosion, fouling, or assembly yield).

- Then: confirm what “D-type” means for your build (profile, end-form, tube-to-header interface, or packing geometry).

- Next: lock the specs that drive real outcomes (dimensions, tolerance, alloy/material, cleanliness, test method).

- Finally: align with a supplier who can prove consistency via inspection records and process controls—not just a catalog page.

What problems are buyers trying to solve?

Most people don’t go shopping for a D-type Round Condenser Tube because it sounds cool. They do it because something hurts—usually cost, uptime, or both. Here are the pain points I see the most often when teams evaluate tube options for condenser duty:

- Space is tight: the coil area is constrained, but capacity targets stay the same.

- Pressure drop is creeping up: pumps/fans work harder, and power consumption rises.

- Fouling and scaling: performance looks fine at commissioning, then decays after weeks or months.

- Vibration fatigue: tube supports are “good enough” until resonance shows up under certain loads.

- Corrosion surprises: mixed-metal systems, water chemistry shifts, or coastal environments shorten life.

- Assembly yield issues: small dimensional drift causes brazing/welding defects, leaks, or rework.

- Lead-time volatility: you need predictable supply and repeatable quality, not a one-off batch that looks perfect.

The best tube choice is the one that reduces your risk profile for your actual operating conditions. That’s why we should talk about what “D-type” usually implies before we talk about “better heat transfer.”

What is a D-type Round Condenser Tube in practice?

The naming can be confusing, because “D-type” is used differently across industries. In many condenser builds, “D-type” often signals a geometry or interface choice intended to improve packing, contact, or assembly stability, while keeping flow behavior closer to what you’d expect from a round passage.

My practical definition: A D-type Round Condenser Tube is typically engineered to keep fluid flow smooth (a key benefit of round flow paths) while introducing a controlled flat or indexed feature (the “D” intent) that helps with placement, spacing, tube-to-header joining, or contact area utilization—especially in compact coils.

Why does that matter? Because many “performance” problems in condensers aren’t caused by heat-transfer theory—they’re caused by manufacturing variation and field conditions. A tube that is easier to position, easier to join, and less sensitive to minor dimensional stack-up can be worth more than a small theoretical efficiency gain.

If you’re evaluating this tube type, don’t just ask “Is it round?” Ask: What part of my build becomes more stable or more repeatable because of the D-type design intent?

Where does it fit best in condenser systems?

In condenser applications across industrial facilities and HVAC systems, tube choice is usually a balancing act between heat-transfer area, flow distribution, and mechanical resilience. A D-type Round Condenser Tube is often chosen when:

- You need compactness: tighter coil packing or more predictable tube alignment helps hit capacity targets in the same envelope.

- You want stable flow behavior: round-like flow paths can help minimize abrupt pressure penalties when compared with more aggressively shaped channels.

- Your joining process needs repeatability: a consistent profile feature can reduce assembly variability.

- Operating conditions swing: vibration, temperature cycling, and intermittent loads reward mechanically stable geometry.

One more reality check: if your condenser is running with inconsistent distribution (hot spots, uneven outlet temperatures), you can lose a lot more performance from maldistribution than you’ll ever gain from an “optimized” tube shape. So treat tube selection as part of a system: headers, supports, fin contact, joining quality, and cleaning strategy.

What to specify so performance matches the drawing

Here’s the trap I’ve seen too many times: the drawing is “complete,” but it doesn’t control the details that actually govern leakage risk, pressure drop, and assembly yield. If you want a D-type Round Condenser Tube to behave consistently batch to batch, these are the specification items that pay off.

Core specs to lock down

- Outer diameter & wall thickness: include tolerance and measurement method.

- Length & cut quality: burr limits, squareness, and end-condition requirements.

- Material/alloy: match to corrosion environment and joining process.

- Surface condition & cleanliness: control oils, chips, dust; define acceptable surface defects.

- Pressure/Leak test: specify test pressure, medium (air/water), hold time, and acceptance criteria.

- Dimensional stability after forming/joining: if tubes are pre-formed or end-worked, specify post-process checks.

If you’re sourcing internationally, it’s also smart to specify packaging and handling requirements. Condenser tubes can be damaged by seemingly minor impacts: denting, ovalization, scratched surfaces, and contamination. Those defects might not show up until joining or pressure testing—when the rework is far more expensive.

How to think about corrosion, fouling, and vibration

“Durable” isn’t a single attribute. For condenser tubes, durability is usually the product of chemistry (corrosion resistance), physics (vibration and fatigue), and operations (fouling and cleaning). Here’s how I’d break it down when deciding whether a D-type Round Condenser Tube is the right move.

Corrosion

- Water chemistry matters: chloride level, pH, dissolved oxygen, and biocide programs change corrosion behavior.

- Mixed-metal systems: galvanic couples can quietly accelerate damage if not isolated or treated.

- Surface protection: coatings or cladding strategies can help, but only if your cleaning method won’t strip them.

Fouling and scaling

- Expect performance decay: build in cleaning access and choose tube specs that tolerate your cleaning approach.

- Velocity trade-off: higher velocity can reduce deposits but may increase erosion or pumping energy.

- Maintenance reality: if your team can only clean twice a year, choose a design that stays stable between cleanings.

Vibration and fatigue

- Support strategy: tube geometry can help, but supports and spacing often decide the final fatigue life.

- Thermal cycling: repeated expansion/contraction can work joints loose if tolerances drift.

- Resonance risk: if your equipment has known vibration bands, check tube/support natural frequencies early.

If you’re buying for uptime, ask for evidence of consistency. For example, Sinupower Heat Transfer Tubes Changshu Ltd., like many serious manufacturers in this category, positions this tube type around reliable heat-transfer service and stable flow behavior—your job is to make those claims “real” by tying them to measurable acceptance criteria in your PO and inspection plan.

Supplier questions that prevent expensive rework

If I had to pick one mindset shift for buyers, it’s this: don’t just evaluate the tube—evaluate the process that makes the tube. When you’re sourcing a D-type Round Condenser Tube, these questions are the ones that tend to expose risk early:

- How do you control dimensional drift across batches? Ask what gets measured, how often, and what happens when it’s out of spec.

- What does “clean” mean in your factory? Ask about chip removal, oil control, and packaging after final inspection.

- What test is standard and what is optional? Pressure test, eddy current (if applicable), visual grading, hardness checks—make it explicit.

- Can you provide inspection records with shipments? If the answer is vague, treat it as a signal.

- How do you prevent handling damage during transport? Dents and scratches can turn into leaks and scrap.

- What is your change-control practice? Material source changes or tooling changes should be communicated before the shipment arrives.

Good suppliers won’t be offended by these questions. They’ll be relieved you’re serious—because serious customers reduce misunderstandings and emergency firefighting.

Selection & troubleshooting table

Use this table as a quick “buyer’s map” for matching common condenser problems with what you should specify or verify when choosing a D-type Round Condenser Tube.

| Buyer pain point | What usually causes it | What to specify / verify | What to watch out for |

|---|---|---|---|

| Capacity drops over time | Fouling, scaling, poor cleaning access | Cleaning method compatibility; surface condition; maintenance interval assumptions | Aggressive cleaning can damage coatings or joints |

| High pressure drop | Flow restriction, maldistribution, rough internal surfaces | Flow path intent; dimensional tolerance; internal cleanliness | “Small” tolerance shifts can become big system penalties |

| Leak failures after joining | End quality issues, contamination, mismatch with header interface | Cut squareness/burr limits; cleanliness standard; leak test plan | Contamination often hides until final pressure test |

| Vibration noise / fatigue cracks | Support spacing, resonance, thermal cycling stress | Support strategy; material selection; dimensional stability after forming | Don’t treat tube geometry as a substitute for proper supports |

| Corrosion and early replacement | Water chemistry, mixed metals, environment exposure | Material/alloy choice; isolation strategy; corrosion allowance | “One-size-fits-all” material choices rarely survive harsh sites |

| Low assembly yield | Batch inconsistency, handling damage, unclear acceptance criteria | Inspection records; packaging; defect limits; change-control expectations | Rework costs often exceed tube price differences |

FAQ

Is a D-type Round Condenser Tube only for one industry?

Not necessarily. The same tube concept can show up anywhere compact condensers and stable joining matter. What changes is the specification: material, tolerance, and testing should match your operating conditions (temperature, fluid chemistry, vibration profile, cleaning method).

What should I prioritize first: heat transfer or reliability?

In most real installations, reliability wins. A slightly “less optimal” tube that maintains performance for months with predictable cleaning and fewer leaks often produces better total cost outcomes than a design that starts strong but degrades quickly or complicates assembly.

How do I avoid ordering the wrong “D-type” interpretation?

Treat “D-type” as a flag to clarify geometry and interface details. Confirm cross-sectional intent, end conditions, and how the tube mates with headers and supports. Add sketches, tolerances, and inspection points to your purchasing documents so there’s no ambiguity.

Do I need special quality checks for these tubes?

If the condenser is critical, yes. At a minimum, define dimensional checks, cleanliness requirements, and a leak/pressure test method. For higher-risk systems, require batch inspection records and clear defect limits (dents, scratches, ovality, burrs).

What’s the fastest way to reduce leak risk?

Lock down end quality, cleanliness, and handling/packaging. Many leaks begin as tiny issues—burrs, contamination, or handling dents—that only reveal themselves during joining or late-stage pressure testing.

Closing thoughts

A D-type Round Condenser Tube can be a smart answer when you’re fighting space constraints, pressure-drop creep, or assembly yield problems—especially when your team needs a tube that behaves predictably under real operating stress. The key is to buy the right version of “D-type” for your condenser architecture, then back it up with the specs and inspection discipline that keep performance consistent across shipments.

If you’re planning a new condenser build or replacing tubes in an existing system, Sinupower Heat Transfer Tubes Changshu Ltd. can support you with product options and manufacturing know-how tailored to condenser service. Share your operating conditions, target capacity, and key dimensions, and we’ll help you narrow down a tube specification that fits your constraints. Ready to move forward? Contact us to discuss your project and get a quotation that aligns with your real-world requirements.