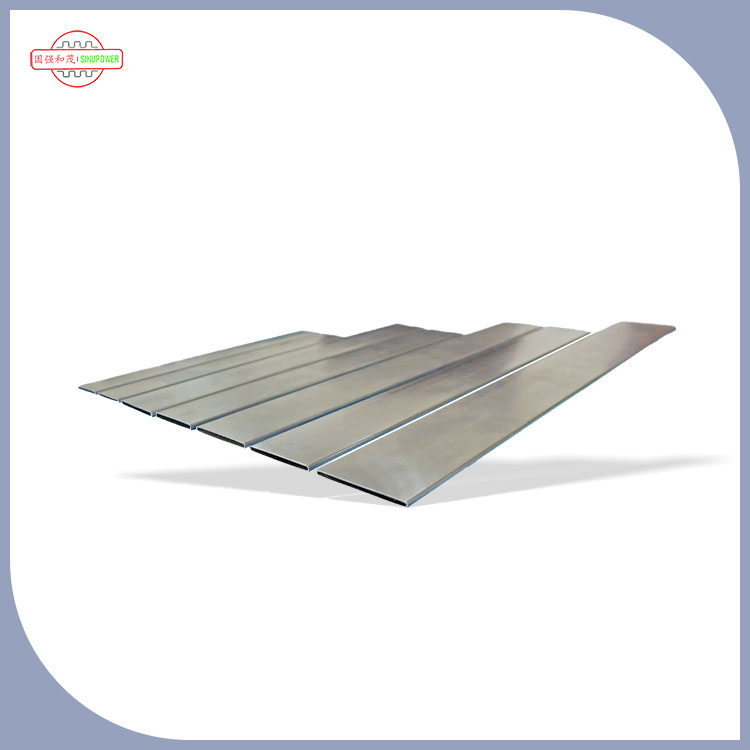

Welded B-Type Tubes for Radiators are a common radiator component with unique structural and performance characteristics. The following is a brief introduction to it:

1.Structural characteristics: B-type pipes are usually composed of multiple parallel arranged steel pipes, which are firmly connected to the two end headers through welding processes, forming a B-type layout. There is a welding surface in the middle of the pipe body, and a reinforced partition can be set at the welding surface to improve the strength and pressure resistance of the pipe body. The diameter and wall thickness of the steel pipe are determined according to actual usage needs. Generally, the diameter of the steel pipe is 57-108 millimeters and the wall thickness is 3.5-5 millimeters.

2.Welding process: High frequency welding technology or brazing is used to weld B-type pipes. High frequency welding utilizes the skin effect and proximity effect generated by high-frequency current to rapidly raise the temperature of the steel pipe to the welding temperature, and then through compression, promotes the bonding of metal atoms to form a dense and high-strength weld seam. Hard brazing is the use of a metal material with a lower melting point than the workpiece as the brazing material. The workpiece and brazing material are heated to a temperature higher than the melting point of the brazing material but lower than the melting point of the workpiece. The liquid brazing material is used to wet the workpiece, fill the interface gap, and achieve atomic diffusion with the workpiece, thereby achieving welding.

3.Performance advantages:

High heat dissipation efficiency: The B-type tube has a simple design with no complex fins, making it less prone to dust accumulation. The internal channels are smooth, and the resistance of the heat medium flowing inside the tube is low, ensuring smooth circulation and efficient heat dissipation. At the same time, the B-type layout makes the heat distribution more uniform, and the circulation of hot air is smooth, which can quickly increase the temperature of the space.

Strong pressure bearing capacity: The sturdy welded structure endows B-type pipes with strong pressure bearing capacity, generally able to withstand working pressures of 1.0-1.6MPa, which can meet the centralized heating needs of large spaces such as large buildings and industrial plants, and is also suitable for steam heating systems.

Long service life: High frequency welding technology or hard brazing form makes the weld strength high, reduces welding defects, and lowers the risk of leakage. Moreover, through strict screening of steel pipe materials and professional surface anti-corrosion treatment, even in humid and corrosive environments, B-type pipes can work stably for a long time, with a service life of more than 20 years.

4.Application scenarios: Welded B-Type Tubes for Radiators are suitable for various scenarios, such as industrial workshops, large warehouses, sports venues, large shopping malls, and other places that require high heat output. In these places, B-type pipes can reliably provide heating due to their efficient heat dissipation performance, strong pressure bearing capacity, and long service life, creating a comfortable indoor environment for people, while also meeting the temperature control needs in some industrial production processes.