The battery cooling plate (also commonly known as the "battery cooling plate") is the core thermal management component of battery systems, especially high-power/high-capacity battery packs such as new energy vehicle power batteries and energy storage batteries. Its core function is to control the temperature of the battery during charging and discharging through active or passive means, ensuring that the battery always operates in a safe and efficient temperature range, avoiding performance degradation, shortened lifespan, and even safety risks (such as thermal runaway) caused by overheating or uneven temperature.

1、 Core role: Around the three core values of "temperature control"

1. Suppress battery overheating and avoid safety risks

Batteries (especially lithium-ion batteries) generate Joule heat during charging and discharging (current does work and generates heat through internal resistance), and under high-power conditions (such as rapid acceleration and fast charging of new energy vehicles), the heat generation will increase sharply:

If the temperature exceeds the safe threshold (usually 45-60 ℃ for lithium-ion batteries, with slight differences for different types), it may cause electrolyte decomposition, structural damage to positive electrode materials, and even trigger "thermal runaway" (fire, explosion);

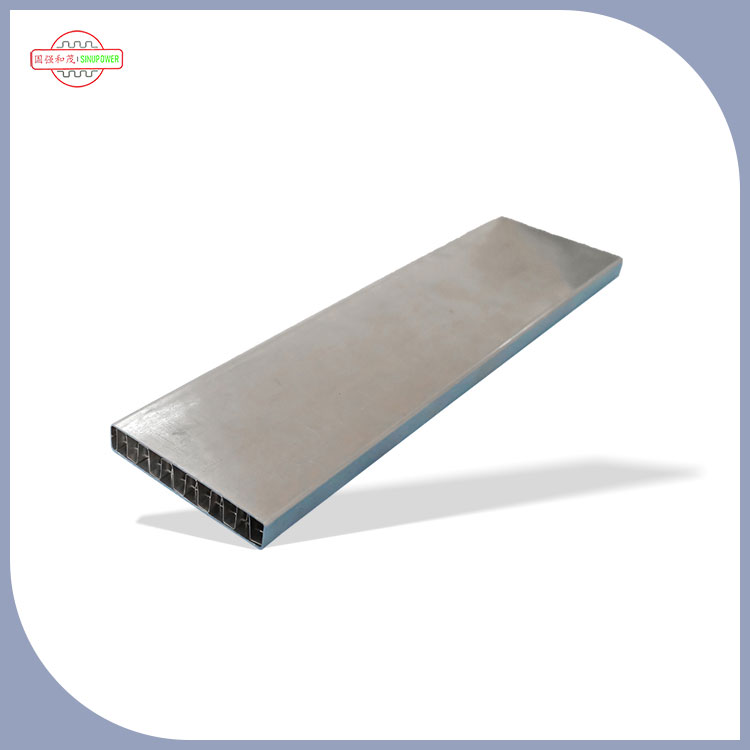

The cooling plate quickly absorbs heat and conducts it to the cooling medium (such as coolant, air) by directly or indirectly contacting the surface of the battery (such as bonding to the battery cell/module), controlling the battery temperature within a safe range and reducing the risk of thermal runaway from the source.

2. Balance battery temperature difference to ensure stable performance

A battery pack is composed of dozens or even hundreds of individual cells. If the heat dissipation is uneven, there may be a temperature difference problem of "local high temperature, local low temperature" (such as a temperature difference of more than 5 ℃ between the edge and center of the battery pack):

High temperature monomer: faster capacity decay and shorter cycle life;

Low temperature cells: low charging and discharging efficiency (such as reduced winter range), and even unable to participate in charging and discharging normally, causing the entire battery pack to be "lagging behind";

The cooling plate is designed with uniform flow channels (such as serpentine channels, parallel channels) or heat dissipation structures to ensure that heat is evenly carried away, reduce the temperature difference between individual cells (usually required to be controlled within 3-5 ℃), and enable all battery performance to be synchronized, avoiding the "barrel effect".

3. Maintain optimal operating temperature and extend battery life

The battery has an "optimal operating temperature range" (usually 20-40 ℃), within which:

The highest charging efficiency (avoiding slow low-temperature charging and lithium deposition during high-temperature charging);

The capacity decay is the slowest (high temperature accelerates the aging of electrode materials, low temperature leads to the formation of lithium dendrites, both of which shorten the lifespan);

The cooling plate dynamically adjusts the heat dissipation intensity (such as automatically starting and stopping the cooling system according to the battery temperature, adjusting the coolant flow rate), stabilizing the battery in the optimal range for a long time and significantly extending the service life of the battery pack (usually extending the service life of the power battery from 3-5 years to 5-8 years).

2、 Auxiliary function: Function extension adapted to different scenarios

Compatible with low-temperature preheating (partially integrated design): Some cooling plates adopt a "cold hot integration" structure (such as integrating heating elements in the flow channel), which can be switched to "heating mode" during low temperatures in winter. The battery is preheated through coolant/heating fins, solving the problems of low battery activity and short range at low temperatures (especially suitable for new energy vehicles in cold northern regions).

Protecting battery structure and reducing vibration impact: Some cooling plates (such as the water-cooled plate of new energy vehicle power batteries) are equipped with cushioning materials (such as thermal conductive silicone pads) when attached to the battery. In addition to enhancing thermal conductivity, they can also cushion vibrations during vehicle operation, avoiding structural looseness or poor electrode contact of battery cells due to long-term vibration.

3、 Key adaptation scenario: Why do high-power batteries rely on cooling plates?

New energy vehicle power battery: It is the most core application scenario for cooling plates. Due to the high charging and discharging power of the battery during vehicle operation (such as peak power reaching hundreds of kilowatts), and the enclosed installation space (poor heat dissipation conditions inside the battery pack), it is necessary to use cooling plates (mainly water-cooled plates) to forcibly dissipate heat, otherwise it will seriously affect the range and safety;

Energy storage battery system: The battery pack of large energy storage power plants (such as photovoltaic/wind power matching energy storage) has a large capacity and can be charged and discharged for a long time. If the temperature is too high, the capacity will rapidly decay. Cooling plates can ensure the long-term stable operation of the energy storage system;

High power industrial batteries, such as those used in forklifts and AGV robots, generate a large amount of heat through frequent fast charging and discharging. The cooling plate can prevent the battery from frequently shutting down due to overheating and improve equipment operation efficiency.