Welded B-type pipes for radiators are pipes specifically designed for heat dissipation systems. Their characteristics mainly revolve around heat dissipation efficiency, structural stability, and applicable scenarios, as follows:

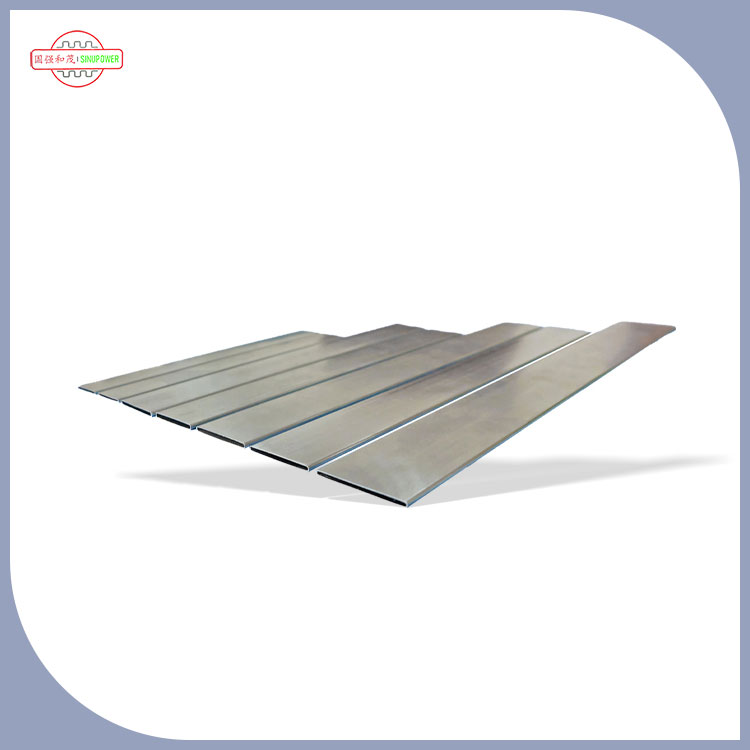

Structural design adapted to heat dissipation requirements: formed using welding technology, the pipe wall is thin and uniform, which helps to quickly conduct heat; Tube type (such as with fins or specific cross-sections) can increase the contact area with heat dissipation media (air, coolant, etc.), improving heat dissipation efficiency.

Excellent material and welding performance: Metals with good thermal conductivity (such as copper, aluminum, or alloys) are often used, and the welding joints have strong sealing and are not prone to leakage, ensuring stable medium circulation in the heat dissipation system while withstanding certain temperature changes and pressures.

Lightweight and space adaptability: Compared to thick pipes, welded B-type pipes are lighter in weight and can be designed to be bent or folded according to the radiator structure, saving installation space and suitable for small-sized or compact layout heat dissipation equipment.

Cost and mass production advantages: The welding process is mature, easy to mass produce, and the cost is relatively controllable, which can meet the needs of large-scale applications in the radiator industry. At the same time, the pipe specifications can be adjusted to adapt to different power dissipation scenarios (such as automobiles, home appliances, industrial equipment, etc.).