The reason why factories choose elliptical flat pipes (flat pipes with elliptical cross-sections) is closely related to their unique structural advantages, performance characteristics, and adaptability to application scenarios. Analyze its core driving forces from multiple dimensions as follows:

1、 Optimization of Fluid Dynamics Performance

1. Reduced resistance and increased flow rate

Streamline design: The long axis direction of the elliptical flat tube conforms to the streamline characteristics of fluid (gas, liquid) flow. Compared with circular pipes, it can reduce fluid eddies and turbulence at the same cross-sectional area, and lower resistance along the way (reducing pressure drop by about 10% -15%), especially suitable for ventilation, air conditioning, and water supply and drainage systems.

Flexible and adjustable aspect ratio: By adjusting the ratio of the major axis to the minor axis of the ellipse (such as 2:1, 3:1, etc.), the fluid velocity distribution can be optimized, and the flow rate can be increased in a limited space (for example, after transforming a rectangular air duct into an elliptical flat tube, the air volume can be increased by more than 20%).

2. Anti clogging and self-cleaning ability

Asymmetric cross-section advantage: The flat structure of the elliptical flat tube can reduce the deposition of solid particles (such as dust and sediment) at the bottom of the pipeline, especially suitable for transporting fluids containing impurities (such as industrial wastewater and slurry), reducing the risk of blockage.

2、 Space utilization and installation convenience

1. Save installation space

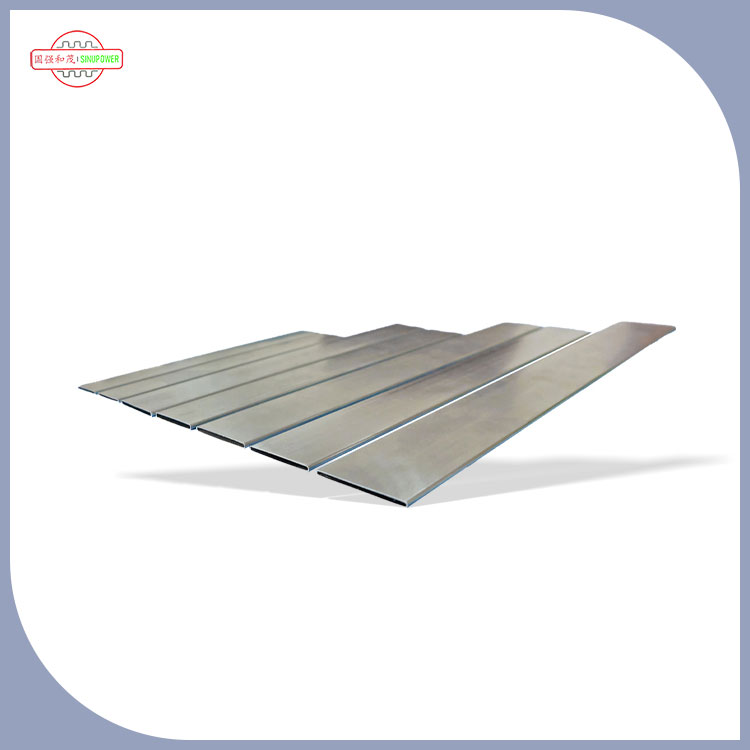

Flat form is suitable for narrow environments: The height (short axis) of elliptical flat pipes is usually lower than that of circular pipes with the same cross-sectional area, making them suitable for installation in factories, equipment interlayers, or dense pipeline areas with limited floor height (such as chemical workshops and high-rise buildings), which can reduce space occupancy by 30% -50%.

Advantages of wall or ceiling installation: Its flat cross-section makes it easy to lay against the wall or ceiling, reducing the impact on traffic or production areas, especially suitable for pipeline layout in automated production lines.

2. Lightweight and construction efficiency

Material consumption reduction: Under the same cross-sectional area, the circumference of elliptical flat pipes is smaller than that of rectangular pipes, and the wall thickness can be optimized for design (such as long axis direction reinforcement structure), which can save 10% -20% of metal materials compared to circular pipes and reduce transportation and installation costs.

Flexible connection method: flange connection, socket connection or welding can be used, combined with prefabricated production (such as factory prefabricated standard length pipe fittings), to improve on-site installation efficiency by more than 50%.

3、 Structural strength and durability

1. Compression and deformation resistance ability

Stress distribution optimization: The long axis direction of the elliptical flat tube has high bending strength, and the short axis direction can be improved in compressive strength by increasing wall thickness or corrugated structure. It is suitable for high-pressure scenarios (such as steam pipelines and compressed air pipelines), and the working pressure can reach 1.6-2.5 MPa.

Improved anti vibration performance: Non circular cross-section can reduce pipeline vibration caused by fluid pulsation (such as pump outlet pipelines), and lower the risk of fatigue damage caused by resonance.

2. Corrosion resistant and wear-resistant design

Wide material compatibility: Stainless steel (304/316), aluminum alloy, carbon steel and other materials can be used to enhance corrosion resistance through surface treatment (such as galvanizing, coating), suitable for harsh environments such as chemical and marine engineering.

Strengthening of wear concentration area: In the transportation scenario of fluid containing particles, the bottom of the elliptical flat tube (wear focus area) can be thickened or lined with wear-resistant materials (such as ceramics and rubber), which can extend the service life by 2-3 times.

4、 Heat exchange and energy-saving advantages

1. Enhance heat transfer performance

Increasing contact area: The flat shape of elliptical flat tubes can increase the contact circumference with external media such as air and cooling water. In heat exchangers such as condensers and evaporators, the heat transfer coefficient is increased by 15% -25% compared to circular tubes, improving heat exchange efficiency.

Turbulence promoting effect: When fluid flows in an elliptical cross-section, it is easy to form secondary flows (such as Dean vortices), which can damage the thickness of the boundary layer and enhance convective heat transfer, especially suitable for refrigeration systems and HVAC equipment.

2. Significant energy-saving benefits

Reduce energy consumption: Due to reduced resistance and increased flow rate, the power of supporting power equipment such as pumps and fans can be correspondingly reduced. Under long-term operation, the energy-saving rate can reach 10% -15%, which is suitable for high energy consuming factories such as steel, paper, and food processing.