From construction to furniture design, rectangular tubes have become a fundamental building block across industries. These hollow structural sections offer an ideal balance of strength and efficiency, providing exceptional load-bearing capacity while minimizing material use. Their flat surfaces and right-angle edges make them easier to work with than round tubes for many applications, simplifying fabrication and assembly processes.

Rectangular tubing is manufactured through various processes including hot-rolling, cold-forming, and welding, with materials ranging from structural steel to aluminum and stainless steel. The dimensions and wall thickness can be precisely specified to meet project requirements, allowing engineers to optimize strength-to-weight ratios. This versatility makes them suitable for everything from heavy industrial frameworks to delicate architectural features.

The geometry of rectangular tubes provides inherent advantages that circular tubes can't match. Their flat surfaces offer better contact points for connections and attachments, reducing the need for complex mounting hardware. When used as beams, their shape provides superior resistance to bending in the strong axis while maintaining good torsional stability. This makes them ideal for applications like building frames, vehicle chassis, and support structures where multi-directional strength is required.

In architectural applications, rectangular tubes deliver clean lines and modern aesthetics while serving structural purposes. Their hollow nature allows for convenient routing of electrical wiring, plumbing, or other services through the center. Aluminum rectangular tubes have become particularly popular for storefronts, railings, and curtain walls due to their corrosion resistance and sleek appearance.

For fabricators, rectangular tubes simplify manufacturing processes. They're easier to cut, drill, and weld than many alternative profiles, with consistent dimensions that ensure precision in assembly. Their standardized sizes and availability make them a cost-effective choice for both small-scale projects and large industrial applications.

When selecting rectangular tubing, engineers consider factors like material grade, wall thickness, and surface finish based on the project's structural requirements and environmental conditions. Proper specification ensures optimal performance whether the tubes will be painted, powder-coated, or left with a natural finish.

From skyscraper skeletons to DIY furniture frames, rectangular tubes continue to prove their worth as one of the most practical and adaptable building materials available. Their combination of strength, workability, and clean aesthetics ensures they'll remain a go-to solution for designers and builders tackling projects of any scale.

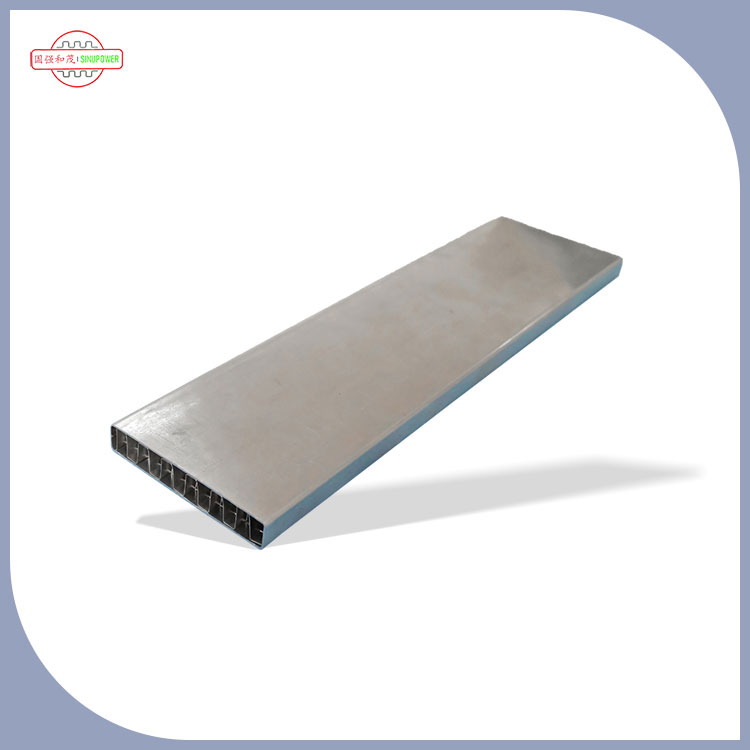

Sinupower develops and manufactures new energy precision pipes of various thicknesses, shapes and sizes, such as folded pipes, rectangular pipes, flat pipes, round pipes, D-shaped pipes, hollow glass aluminum spacers, etc. These products are widely used in automotive heat exchange, commercial air conditioning, power station cooling, building door and window systems, etc. Visit our website at https://www.sinupower-transfertubes.com/ to learn more about our products. For inquiries, you can reach us at robert.gao@sinupower.com.