The automotive and energy storage industries have recently seen groundbreaking advancements in the development of Battery Cooling Plate Tubes, a crucial component in the thermal management systems of electric vehicles (EVs) and battery energy storage systems (BESS).

These Battery Cooling Plate Tubes are designed to efficiently dissipate heat generated by batteries during operation, ensuring optimal battery performance, longevity, and safety. The latest innovations in this field focus on enhancing the cooling efficiency, material durability, and overall design of these tubes to meet the increasing demands of high-performance EVs and large-scale BESS.

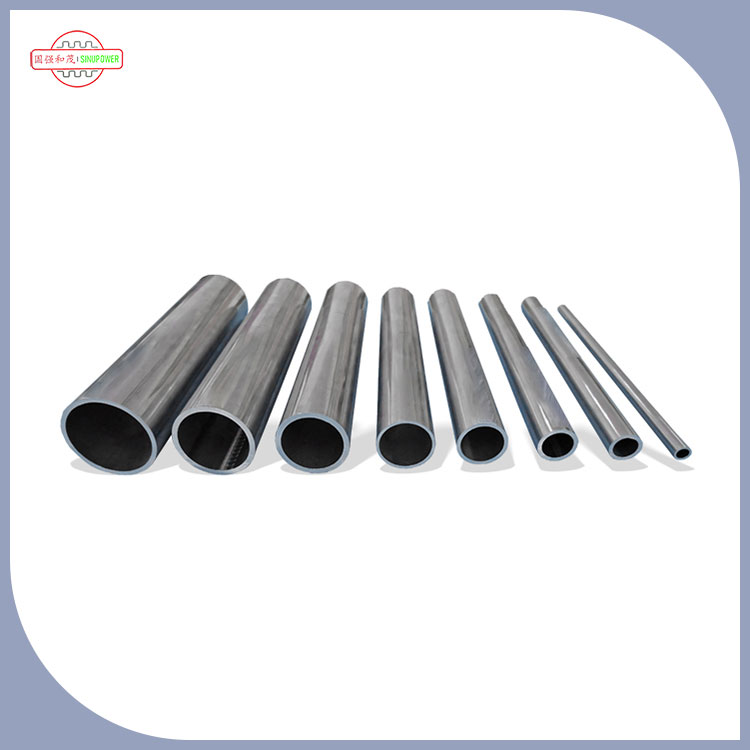

One significant breakthrough involves the use of advanced materials for Battery Cooling Plate Tubes. These materials, such as high-thermal conductivity alloys and composites, provide superior heat transfer capabilities while maintaining structural integrity and corrosion resistance. This allows for more effective cooling and extends the lifespan of the battery system.

Another key innovation is the optimization of the tube design. Engineers are developing more intricate and efficient tube geometries that maximize surface area for heat transfer while minimizing pressure drop and flow resistance. This enhances the overall efficiency of the cooling system and contributes to improved battery performance.

Moreover, manufacturers are incorporating smart sensors and control systems into Battery Cooling Plate Tubes. These systems monitor the temperature and flow rate of the coolant, adjusting the cooling strategy in real-time to maintain optimal battery temperatures. This predictive maintenance approach reduces the risk of thermal runaway and prolongs battery life.

The growing adoption of EVs and the expansion of renewable energy infrastructure are driving the demand for advanced Battery Cooling Plate Tubes. As these technologies continue to evolve, the automotive and energy storage industries can expect even more efficient, reliable, and sustainable battery cooling solutions.